Surfi-Inspect

Surfi-Inspect

surface defects of various products that are difficult to inspect with existing vision systems.

It can be applied to various fields such as:

-

Metal & aluminum products

Eliminates diffused reflections on metal surfaces to detect fine scratch, dent, crack and wrinkle on the surface -

Plastic Injection & Rubber Products

Detect Scratch, dent and cracks on surface without being affected by the color of the injected products. -

PCB & Plated Products

Detect Scratch, dent and foreign substance on plated PCB's surface. -

FPD & Glass Products

Detect Scratch, dent and foreign substance on tempered glass and LCD. -

Film Products

Inspect Scratch, dent and foreign substance on film of roll to roll equipment. -

Bottle, can and PET products

Detect Scratch, dent and foreign substance on glass, aluminum and PET Bottle. -

Paper

Detect Scratch and dent on surface of hologram and printed paper. -

Other Products

Detect optimal state for products whose judgment is unclear in the 2D image.

Surfi-Inspect

Features and Advantages

-

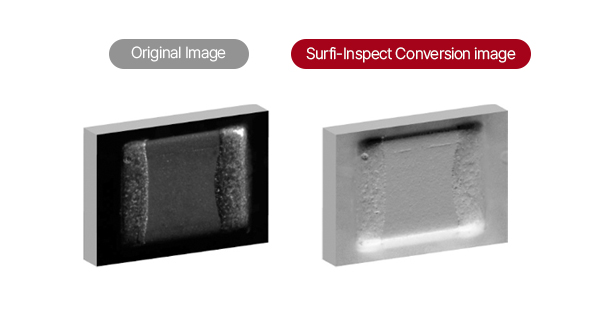

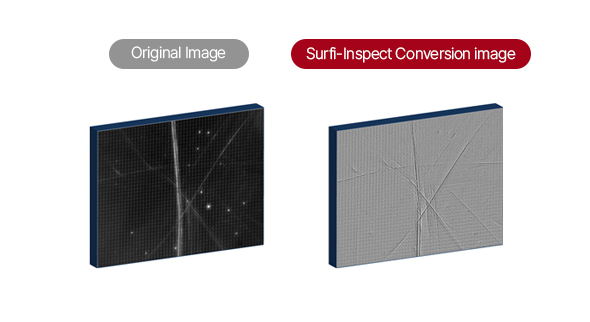

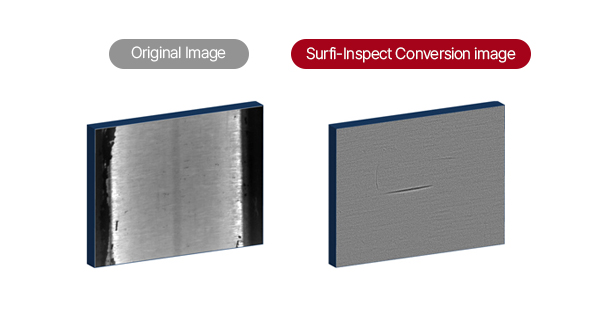

Applying the methods of 2D and 3D image process

On the surfacs of metal and film with severe diffused reflections depending on the angle of the light, you can do the inspection in optimal condition excluding interference of ambient light and protruding the defects of surface. -

Complete surface inspection integrated solution

This is an integrated solution for surface inspection with HW and SW technologies for image processing. -

Ability to inspect products in stationary and moving states

It is a surface inspection product that can use area scan camera and line scan camera, and provides the optimal solution for customer's system. -

Highly precise defect detection

It is a highly precise inspection system that can detect defects that are difficult to detect with the naked eye and defects in microns (um). -

Standardization of system

Standardized optical systems can minimize the time and cost of installation.

Surfi-Inspect applications

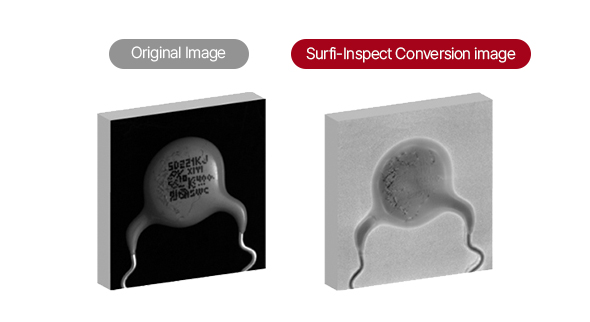

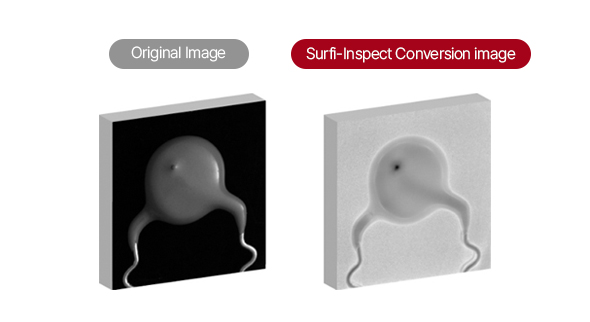

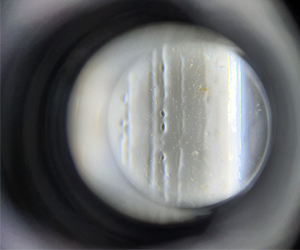

Condenser (injection) surface inspection

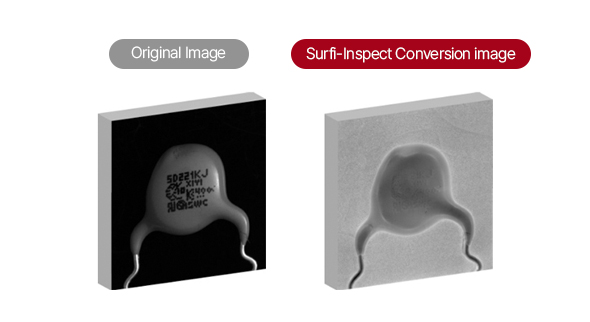

Detect air bubble, scratch, etc. of a condenser with round surface and glossSurface inspection of MLCC(Multilayer Ceramic Capacitor)

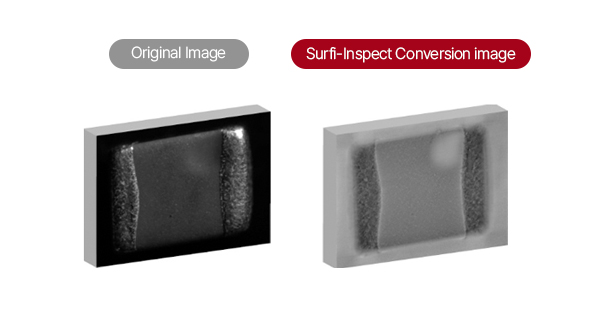

Detect surface defect (imprints, air bubbles, etc.) of MLCCSurface inspection of FPD & Glass

Detect surface microscratch and foreign substance on the surface of the FPD and glass at various anglesMetal rod surface inspection

Accurately detect scratch on the surface even if they are circular such as metal rod.