3D System

3D System

Application Fields

Demand for highly accurate 3D measurements is increasing in various fields such as semiconductors, automobiles, mechanical engineering and medical care. Can be customized 3D system program and UI to meet customer's request, not commercial program which is difficult to handle in production line.-

Semiconductor industry

Measuring thickness of wafer, measuring roughness and waviness, identifying semiconductor's structure and defect. -

Glass industry

Measurement of wall thickness of container glass by non-contact method -

Consumer goods industry

Measuring condition of combination of metal and glass of electronic products such as mobile phones and tablets. -

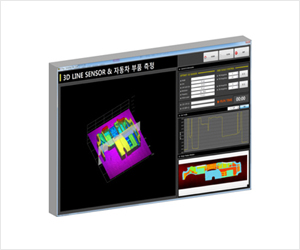

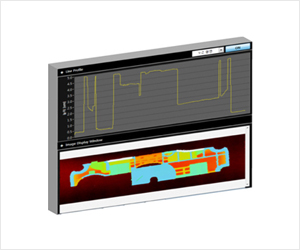

Automobile industry

Measuring surface conditions and line profiles of automotive parts. -

Machine engineering materials

Measure mechanical engineering material surfaces, weld conditions, depth, etc.

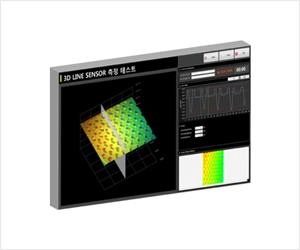

3D System Application Case

-

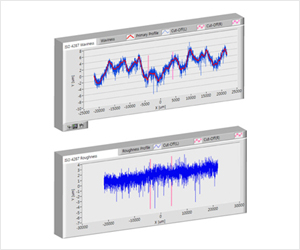

Semiconductor's Roughness & Waviness Measurement

-

Mobile phone's parts - Groove's Depth/Width, Burr Measurement

-

Vehicle's parts - Line Profile Measurement and Analysis

3D System Features

-

Measurement of line scans with high speed

-

Irradiate the light uniformly

-

Replaceable Optical Probe

-

Profile / volume / surface measurement

-

Measurement of roughness / surface waves

-

Inline inspection

-

Easy maintenance

-

Non-destructive measurement